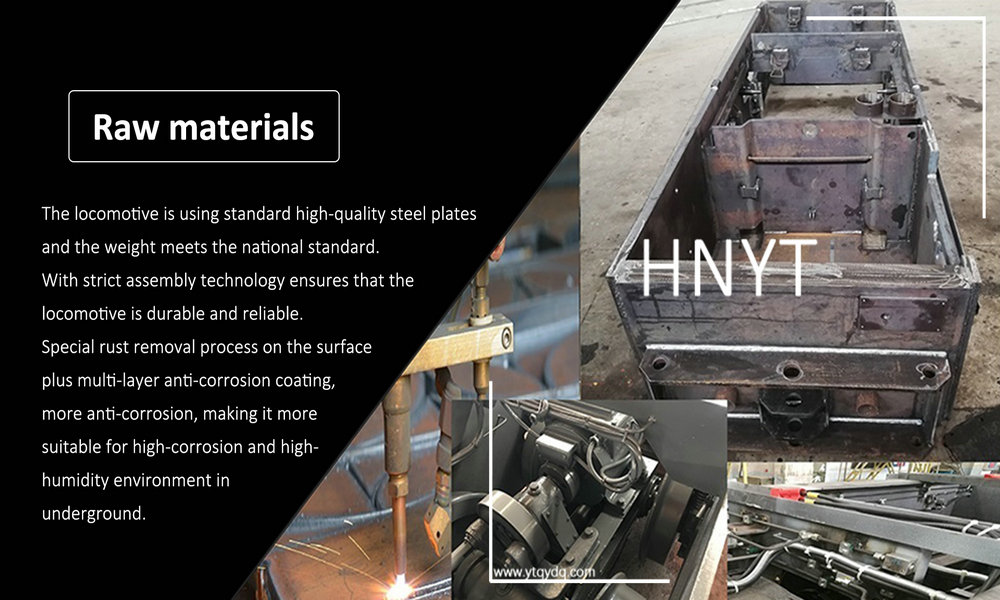

Use high-quality steel plates, which to make sure the weight of the locomotive fully meets the national standard requirements.

Strict assembly technology ensures that the locomotive is durable and reliable.

Special rust removal process on the surface plus multi-layer anti-corrosion coating, more anti-corrosion,

suitable for high-corrosion and high-humidity environment in underground.

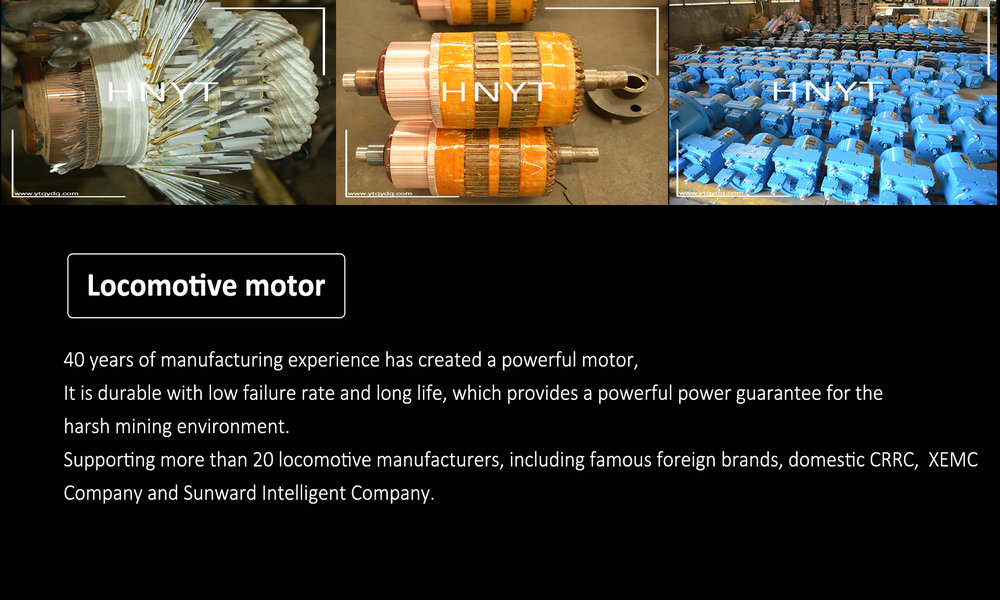

Forty years of manufacturing experience has created a powerful Yutong motor,

Durable with low failure rate and longer life, which provides a powerful power guarantee for the harsh mining environment.

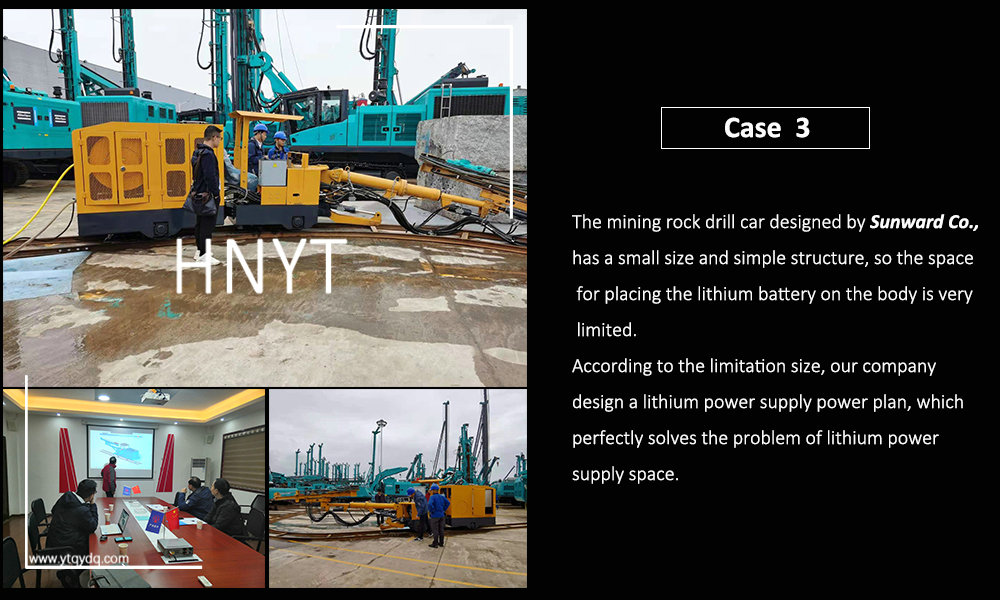

Supporting more than 20 locomotive manufacturers, including famous foreign brands, domestic CRRC, XEMC Company and

Sunward Intelligent Company

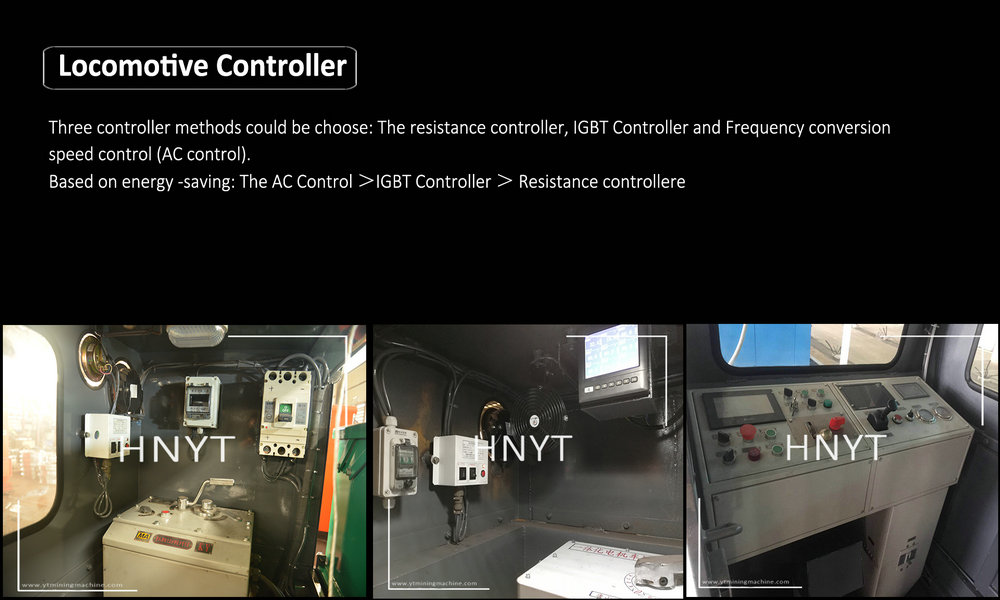

Three controller methods could be choose:

1. the resistance speed control, to control the speed by changing the resistance value, the DC motor works, the commutation

and speed regulation work with copper contact points, which has a short life and is easy to burn out.

2. Chopper speed control(IGBT control), stepless speed control, using chopper speed control technology, adding digital

voltage display module and lighting power module, and the control switch of the electronic horn, the control switch of the front

and rear lights are built in the chopper driver controller, which is easy to operate.

3. frequency conversion speed control(AC control), using frequency conversion control technology, control inverter circuit to

convert DC power to AC power, control AC frequency conversion motor, the whole machine has no contacts, greatly extending

the service life.

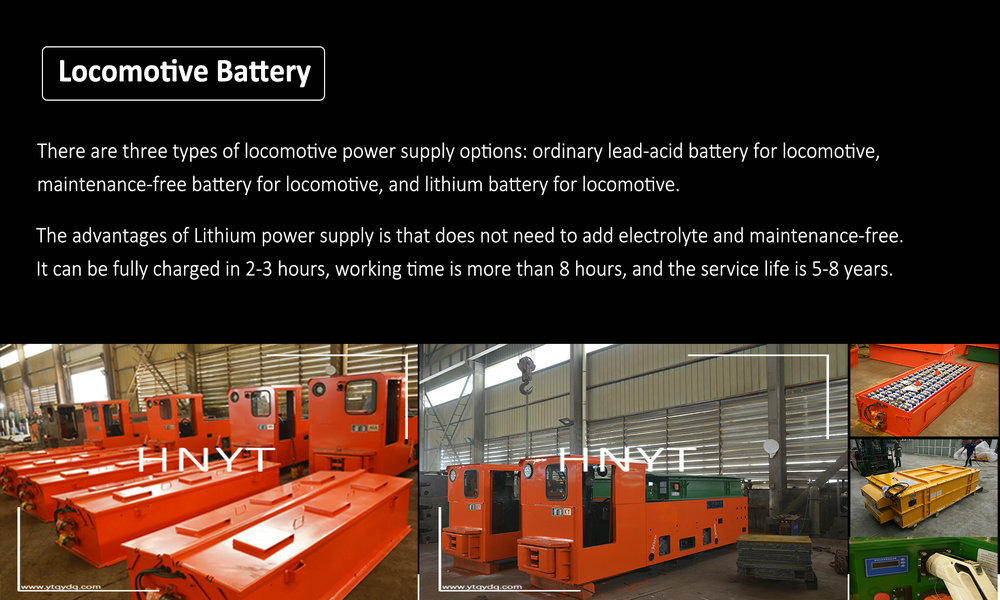

There are three types of locomotive power supply options: ordinary lead-acid battery for locomotive, maintenance-free

battery for locomotive, and lithium battery for locomotive.

1. Ordinary lead-acid power supply needs to be charged with acid and water. The charging time is up to 8-10 hours, the

working time is 8 hours, and the service life is 1-2 years.

2. The maintenance-free power supply requires no water for charging, so the maintenance is simple. The charging time

also takes about 8-9 hours, the working time is 8 hours, and the service life is 1-2 years.

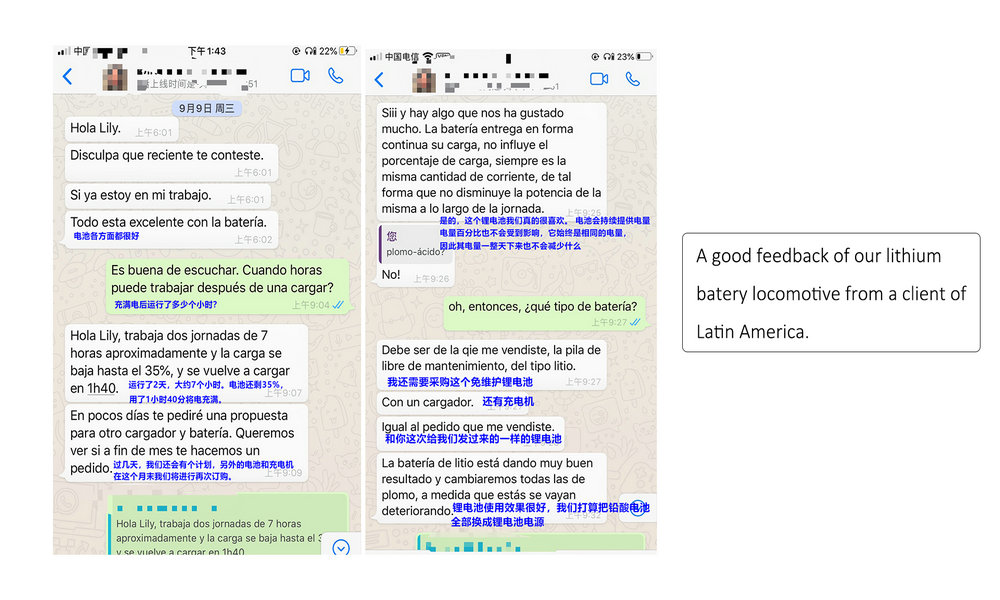

3. Lithium power supply does not need to add water and is maintenance-free. It can be fully charged in 2-3 hours, working

time is more than 8 hours, and the service life is 5-8 years.

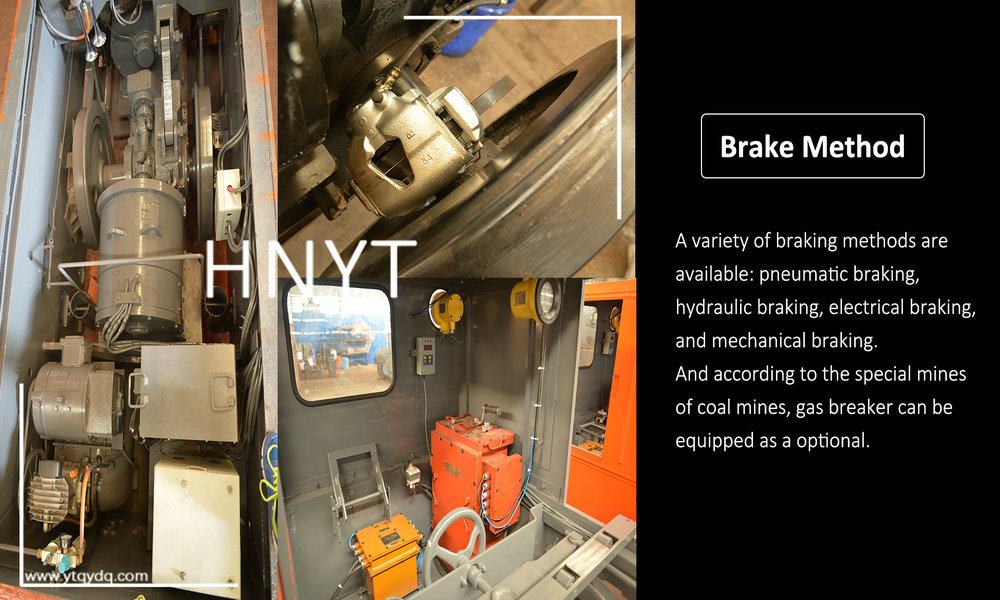

A variety of braking methods are available: pneumatic braking, hydraulic braking, electrical braking, and mechanical braking.

And according to the special mines of coal mines, gas breaker can be equipped as a optional.

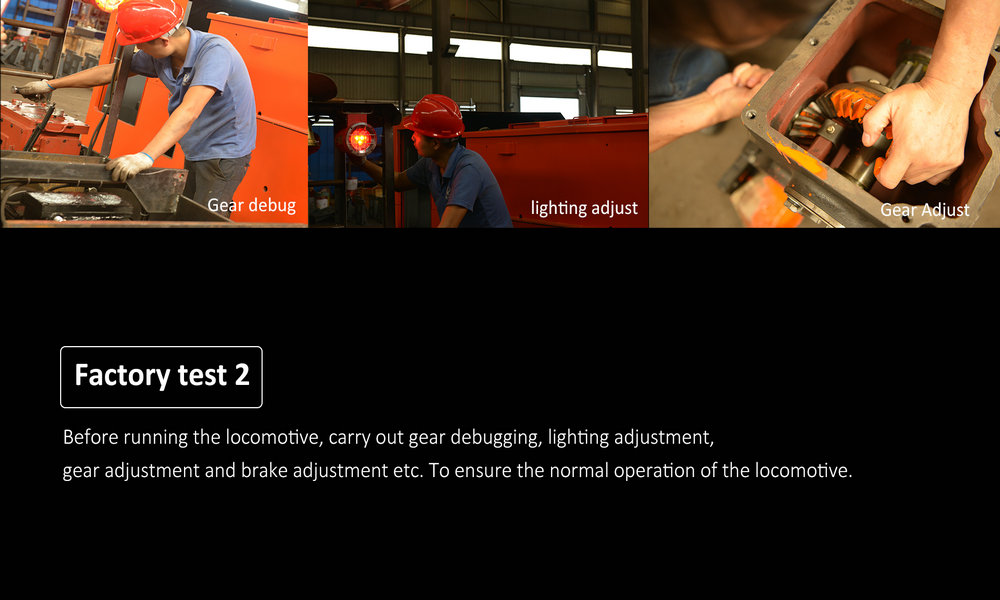

Yutong locomotive requires the gear anastomosis surface to reach more than 80%, far exceeding the standard.

More efficient transmission, lower noise and longer gear life.

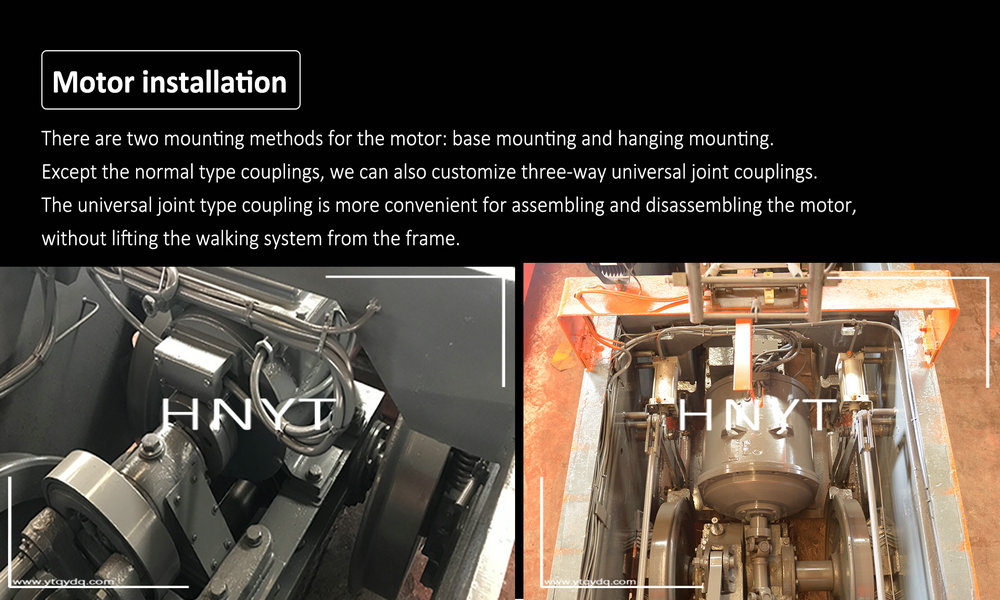

There are two mounting methods for the motor: base mounting and hanging mounting.

In addition to ordinary couplings, we can also customize three-way universal joint couplings. The universal joint type

coupling is more convenient for assembling and disassembling the motor, without lifting the walking assembly from

the locomotive frame.

Professionally designed and adjusted frame ensures safe driving and avoids falling off rails.

Suspension shock absorber system to make you enjoy the comfort of the car.

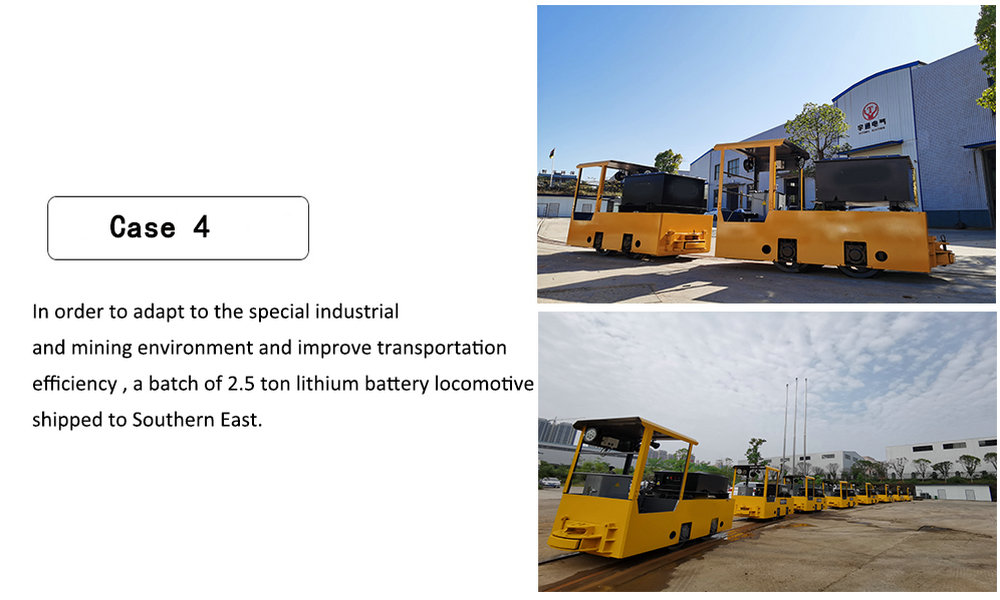

We provide customized production of locomotives for many customers, such as: battery-trolley two use locomotive,

special tools locomotives.

We could also provide South America Type locomotive.

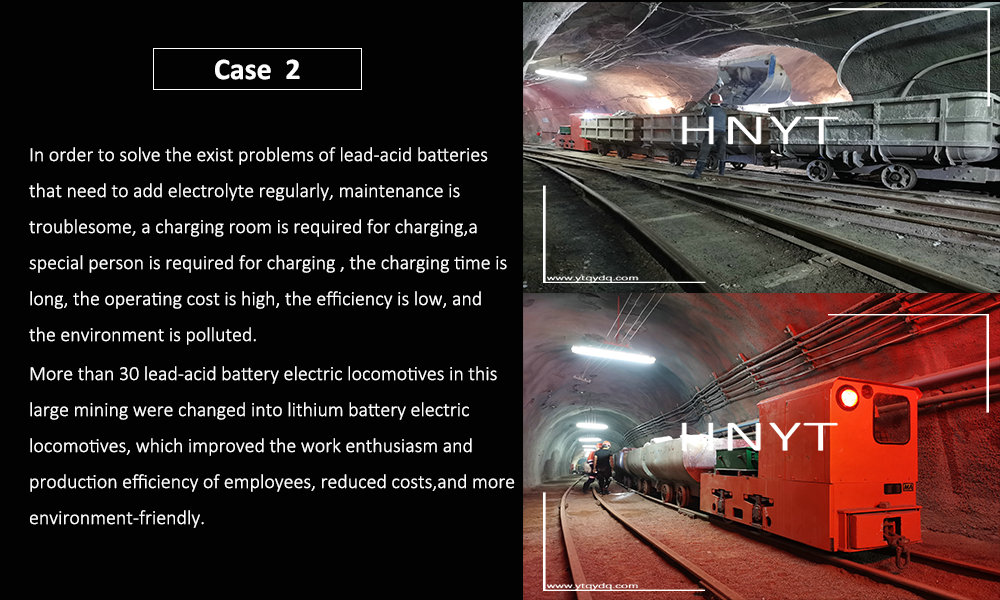

Electric locomotive modification is also provided, for example: locomotive control mode, ordinary resistance is changed to

chopper speed(IGBT) or frequency conversion speed(AC control), ordinary mechanical brake is changed to hydraulic brake or

air brake.

To improved the locomotive's load capacity and to changed the locomotive's ordinary lead-acid battery into a lithium battery.