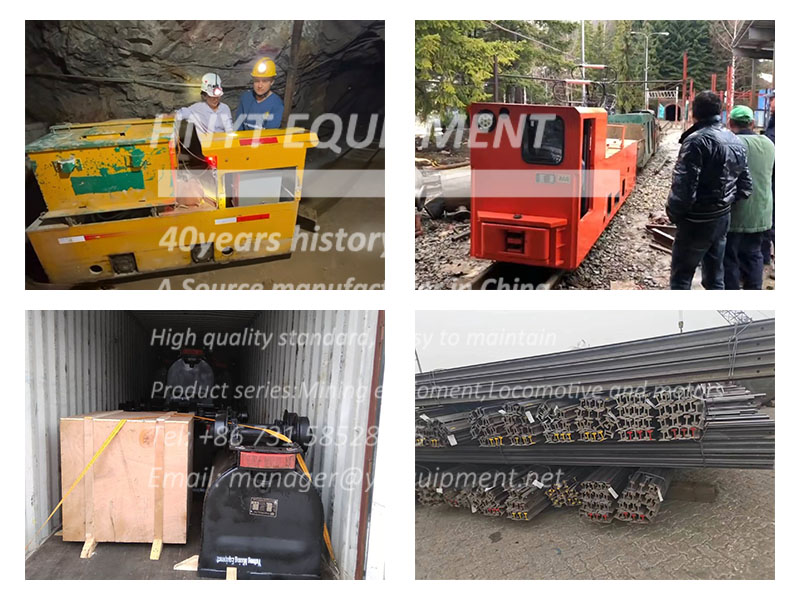

Our factory could provide durable and easy to maintenance underground mining trolley locomotive with competitive price. We have more than 40 years experience to production and design trolley locomotive, covering the market in South America and Africa

Our factory could provide durable and easy to maintenance underground mining trolley locomotive with competitive price. We have more than 40 years experience to production and design trolley locomotive, covering the market in South America and Africa. Hoping to be your long-term partner in China.

The overhead electric locomotive uses cables to provide energy for the locomotive. After the high-voltage alternating current is stepped down and rectified by the transformer, the positive pole is connected to the cable, and the negative pole is connected to the track. The current flows into the locomotive through the cable that is in contact with the pantograph, and then flows through the automatic air switch, controller, and resistance box, and finally enters the traction motor to drive the motor to run. The motor drives the wheels to rotate through the transmission device, and uses the friction between the wheels and the rail surface to make the locomotive move. The current finally flows out of the motor and flows back to the transformer through the track.

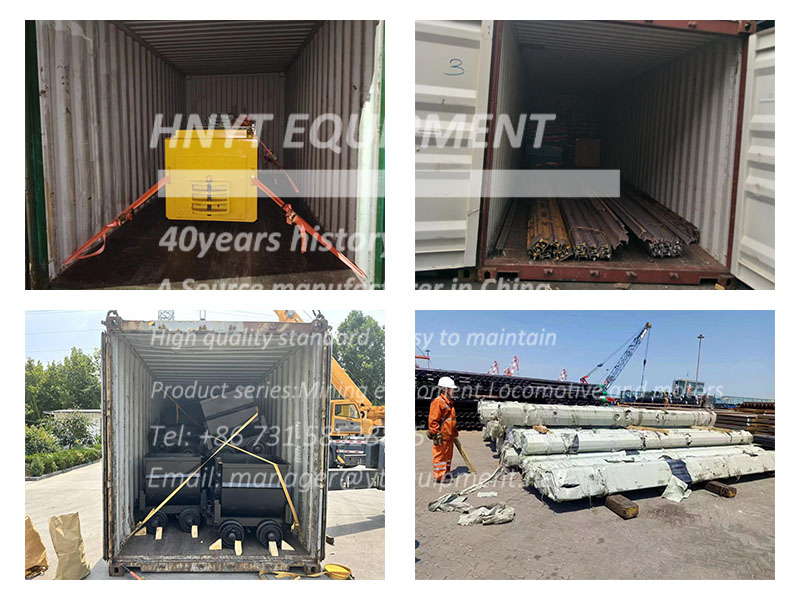

Shipment and one site details